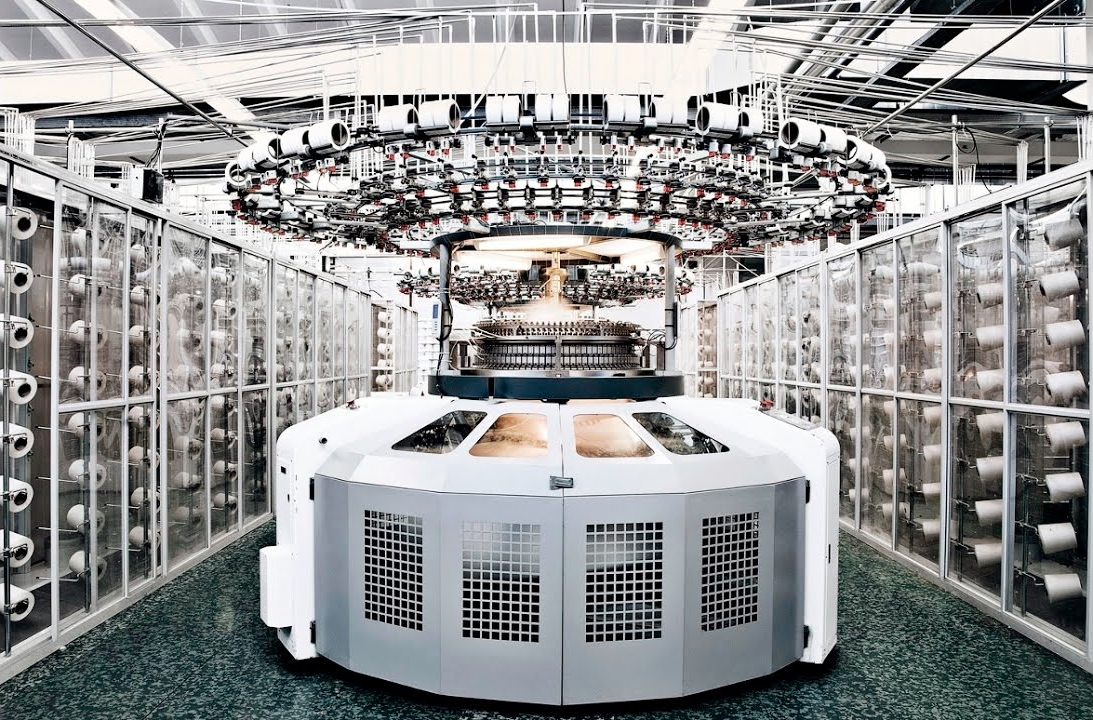

Knitting

Our knitting plants, with Circular & Flat Knitting machines imported from Europe and Asia knit a varieties of fabrics – Jersey, Rib, Interlock, Pique, Feeder & Auto Stripes, Jacquards, with Lycra, flat knit collars, waffle, Fleece in all gauge and feeders. We are capable of producing all kind of specialty fabrics and performance technical fabrics.